Carbon Plant and Rodding Room Practices

Some of the difficulties and problems that are felt in the potroom stem from an anodes quality; poor practices in the rodding room or at the carbon anodes production can lead to increased air burn, carbon dust formation, spikes, and reduced current efficiency. LMRC can help using their extensive experience in the anode production process from raw material to finished anodes, both to fix problems within the anode formation process and design a system to maintain anode quality.

In the anode carbon plant LMRC can help with:

- Carrying out a pitch cost/anode property trade-off assessment.

- Setting up/improving data management for pitch viscosity, temperatures and fractions

- Setting up/improving data management for green anode properties

- Optimising baked anode properties (such as CO2 reactivity, air permeability, flexural strength, baked density)

- Reducing anode cracking.

- Reducing packing coke sticking

LMRC extensive knowledge and experience in carbon plants and rodding room practices can provide the necessary support in each step of the anodes production process to produce optimised anodes with best performance.

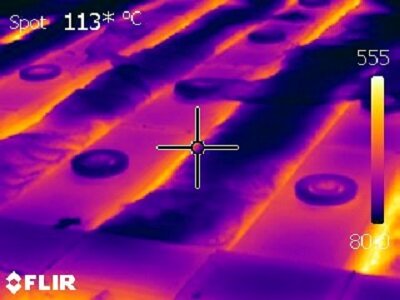

Rodding Room Support

In the rodding room LMRC can:

- Provide technical support for correct cast iron recipe, improving thimble stripping and reduce contamination.

- Improve rodding practices to reduce reactive anode problem.

- Improve an anode’s poor current distribution by improving casting.

Good Quality anodes can not only reduce carbon consumption but also energy consumption, and rework needed to change anodes that failed early in the rota