Fundamental Research Into Alumina

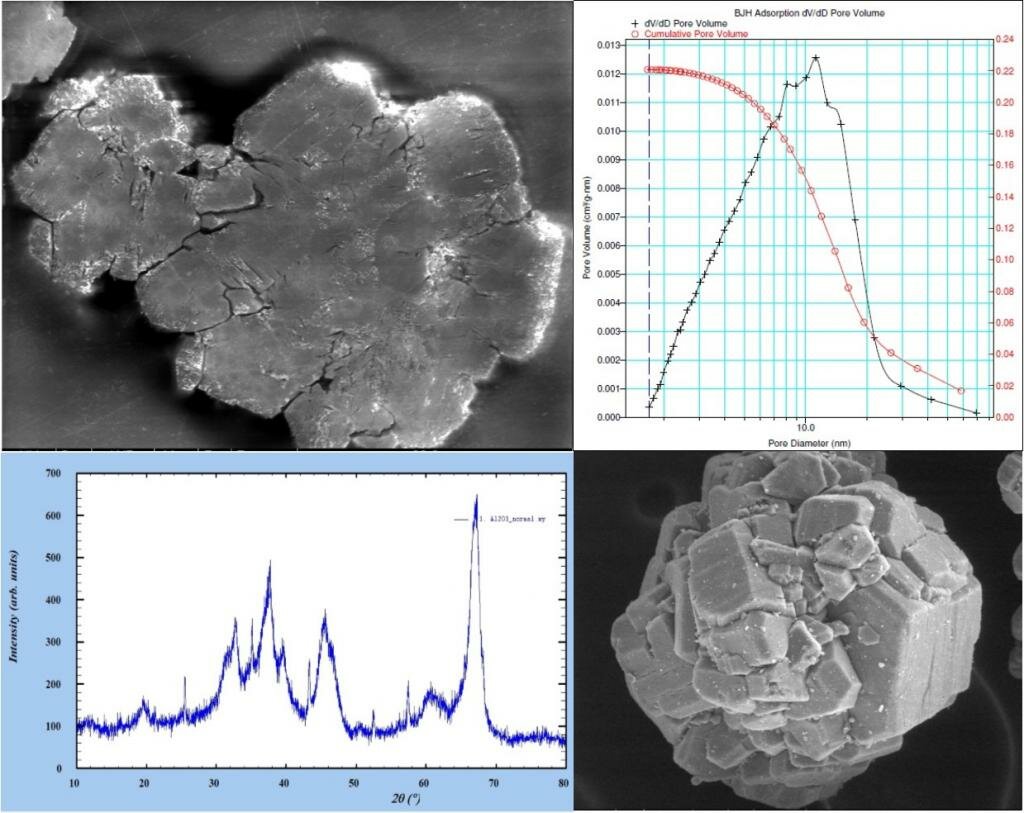

Smelter grade alumina (SGA) is an essential raw material for the aluminium reduction process. This is because of the multiple roles it plays in smelting -: as the primary feedstock, the capture medium for fluoride gases emitted from the reduction cells and as a key constituent of the anode cover materials that prevent heat loss from the top of reduction cells. The multiple roles of alumina in a smelter mean that this material is required to have multiple property specifications. This need to fit all requirements while balancing important economic and energy considerations is not a trivial challenge. Our work at LMRC focuses on studying the evolution of alumina properties with calcination with particular emphasis on alumina agglomerate strength, catalytic behaviour and surface characteristics important for HF scrubbing. In addition to these, we have capabilities and expertise on characterising SGAs using a range of advanced experimental techniques both within the University of Auckland and in external facilities such as the Australian Synchrotron.

Current doctoral studies underway at LMRC:

- Catalytic decomposition & detection of perfluorinated carbons (PFC's) during the aluminium smelting process.

Recent doctoral studies that have been completed at LMRC are:

- Evolution of alumina microstructure and relationships with particle strength.

- Evolution of nano-and microstructure during the calcination of Bayer Gibbsite to produce alumina.

Our recent publication on alumina research: