Technical Support

text_image

text_background

Light Metals Research Centre provides a range of technical support both at the client premises and in our laboratories. Onsite we provide the following services:

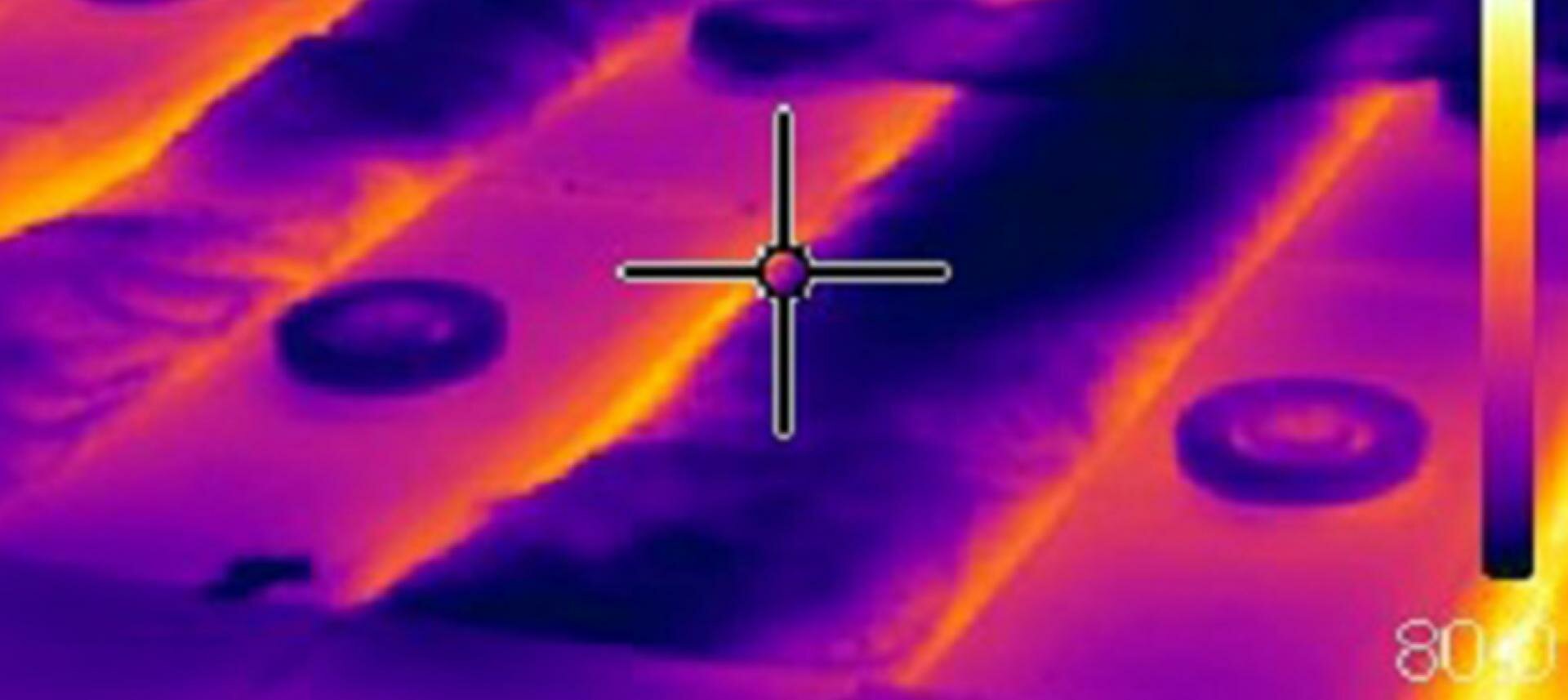

- Smelter Audit - all sections of the facility from the carbon plant to the potroom and bath processing facility

- Operational Technical support - provide the current best practice standards for operation in the potroom, rodding room and anode production facilities.

- Process Control - implement new control strategies on the aluminium reduction process based on our extensive experience.

- Emissions Control - provide expertise in fluoride emissions (summarised in our popular Fluoride Emission Management Guide), PFC's emissions and control of potroom dust emissions.

Light Metals Research Centre provides a range of technical support both at the client premises and in our laboratories

- Material Testing - of cathode materials and sidewall refractories. Our test provides useful information about wear rates of cathode materials and sidewall materials in aluminium reduction environment.

- Microstructure analysis and Characterisation of alumina and bath materials - provides useful information regarding bath chemistry, Cryolite ratio, liquidus point and the various phases in the bath. The alumina analysis that we provide includes phase composition, surface area, pore size distribution, HF adsorption capability and more.

In our laboratories we specialise in testing and characterisation of materials for the aluminium industry