Improving telecommunications covers for a local manufacturer

LMRC has been working with Sika Technology to develop a new product design and alloy combination to improve the performance of telecommunications connection-chamber covers. Studies have focused on the reduction of cover slipperiness for footpaths and roadways, fatigue testing, simulation modelling of various design changes, and ageing of casting products. The results have helped Sika strengthen product quality and significantly increase export volume.

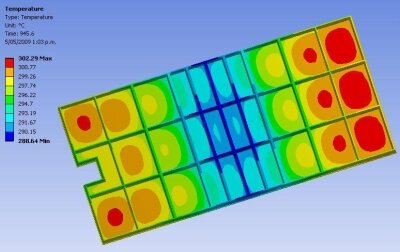

Australian bush fire study

A recent bush fire in Australia prompted Sika to enlist LMRC’s help to test the ability of its telecommunication chamber to withstand a high temperature fire. Aluminium’s thermal conductivity is around four times that of steel, and its specific heat twice that of steel. Where an aluminium structure is exposed to a fire, the relatively high thermal conductivity enables the heat to be rapidly conducted away from the exposed area. This helps to reduce hot spots where significant property loss could occur. In addition, the high reflectivity of weathered aluminium is 80% to 90%, compared to 5% for painted steel and 25% for stainless steel. This is of considerable benefit and can assist in prolonging the endurance of an aluminium structure in a fire. The LMRC’s research and development has successfully increased the thermal resistance of telecommunications chambers; better protecting optical fibers inside the unit in case of fire.