Seeking commercialisation and technology development partnerships

Aluminium reduction cells have been increasing in temperature and heat flow over recent years, to the point where the productivity of large cell technologies is constrained. Removing heat from cell sidewalls for the purposes of temperature control and ledge maintenance presently takes the form of compressed air impingement directly onto the steel shell. These air lances cool in a non-uniform and energy inefficient way, adversely impact the workplace environment through noise and dust generation.

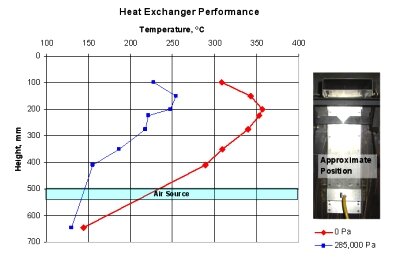

LMRC has developed a sidewall heat exchanger (SHE) technology that has the capability of providing controlled cooling to sidewalls, enabling peak shell temperature reductions of 500-1500C. This would allow a smelter to significantly increase amperage and productivity in the cell while retaining the original design parameters. The technology also serve to to increase the smelters’ power modulation capability when acquire electricity on the spot market; and to recover energy released along the cell sidewalls.

Application and Installation

The primary application for the shell heat exchanger is aluminium smelting cells, where heat extraction from the external surface is required for thermal balance. The goals of the technology are to increase smelter production without substantial increase in capital cost, and ultimately to recycle the energy removed from the cell.

For information flyer, please

click here. For more details, please contact or to discuss the customised installation to fit specific cell technologies.