Alumina Research

Alumina is the raw material for the electrolytic production of aluminium. Effective utilisation of alumina, as well as feeding and dissolution control is critical for smelters to avoid heat perturbations, anode effects, mitigating sludge formation and cathode erosion. Research carried out at the Light Metals Research Centre has clearly demonstrated that the alumina microstructure is of key importance for the performance of the material and that this microstructure is largely influenced by the precipitation and calcination processes in the alumina refinery. Advanced solid state characterization techniques and laboratory test rigs have been developed and used to study:

- Alumina calcination and evolution of properties

- Gibbsite precipitation in the Bayer process

- Alumina nano- and microstructural effects on bulk properties and performance

- Dry scrubbing chemistry

- Anode cover properties and evolution

- HF generation mechanisms and alumina dissolution

Alumina feeding and dissolution related processes in aluminium reduction cells are some of the key areas of interest at the LMRC. We are advancing the combined model approach, whereby all relevant factors are included into a dissolution modeling equation. These models can be used for advanced control algorithms to monitor the feeding and dissolution performance in the pots. This will enable the specific diagnosis of feed related problems and incorporates corrective/preventive actions before large scale sludge formation occurs.

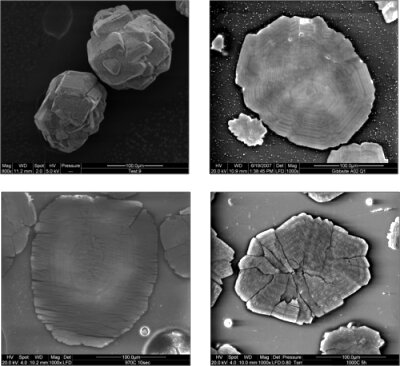

Alumina microstructure as revealed by Environmental SEM

To download our Alumina Research flyer, please click here. For detailed studies and research collaborations, please contact , Associate Director.