Equipments and Facilities

The Centre operates an extensive array of laboratory equipment and facilities for materials characterisation and testing. These are listed below:

- X-Ray Diffractometer with glancing angle attachment and hot stage to identify the compounds and their crystal structures.

- Single crystal X-Ray Diffractometer.

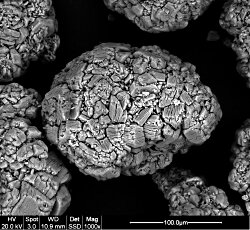

- High-Resolution Field Emission Scanning Electron Microscope with microanalysis unit and cryo-stage for surface morphology and microstructure imaging, elemental and failure analysis.

- Environmental Scanning Electron Microscope (ESEM) for analysis of materials at elevated temperature and gaseous environment.

- Boreal Laser and Hiden quadrupole mass spectrometer for gas emission analysis.

- X-Ray Photoelectron Spectrometer with depth profiling to identify surface composition and chemistry, corrosion mechanisms, nature of surface contamination etc.

- Atomic Force Microscope for investigation of roughness factors, friction and magnetic storage capabilities

- Furnaces of various sizes capable of 1200C.

Analytical and Diagnostic Services

- Material testing and surface modification

- Advanced process analysis and control tools

- Cell dynamic, electromagnetic, thermoelectric modeling

- Testing and development of refractories.

- New electrolysis processes and electrode testing mechanical strength (tensile/yield testing)

- Defect analysis: porosity, casting (HPDC, gravity die-casting, sand casting, investment casting); extrusion defects (surface segregation, flow lines, die lines, etc.).

- Fatigue testing

- Flat surface – COF (coefficient of friction) testing, reduction of slipperiness.

- Micro-structural investigations (SEM, AFM, micro-hardness, etc.)

- Chemical and phase compositions (XRF, XRD, SEM, TEM, XPF, etc.)