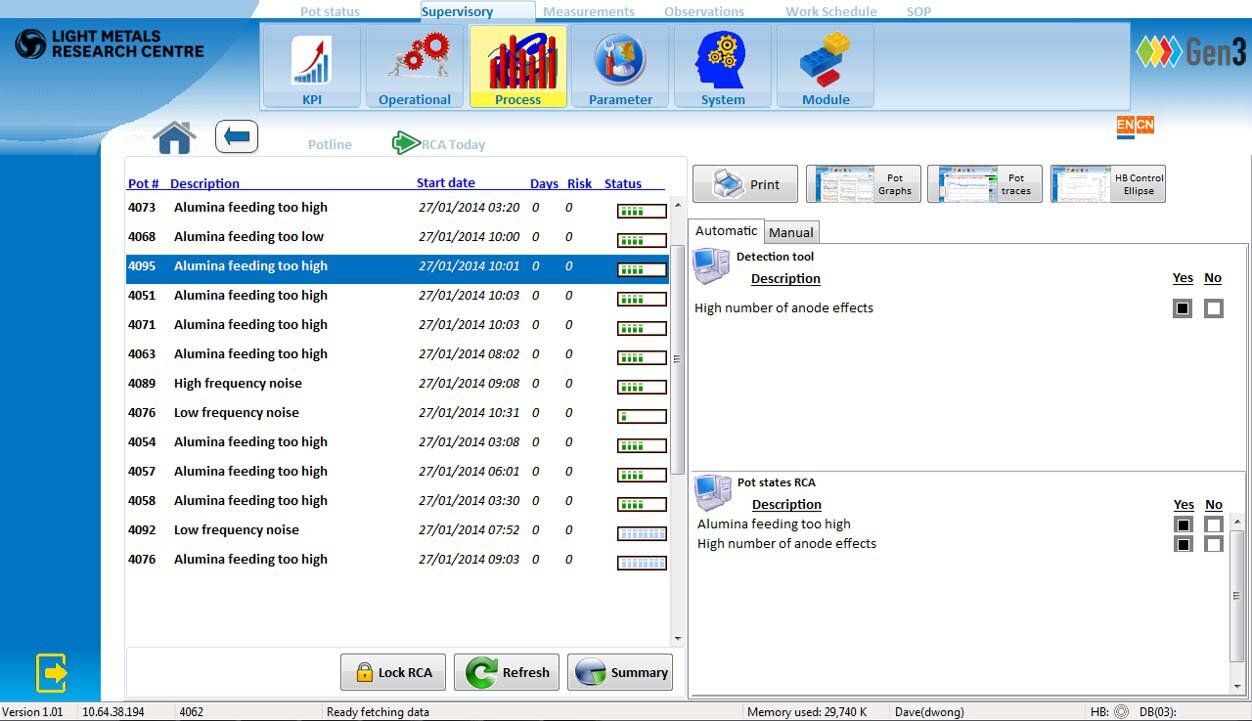

Gen3 has been designed to maximise and simplify system-human integration for continuous process improvement. This system integrates the work of operators, engineers and managers and it learns and adapts to changes and new findings, through continual tracking of diagnosis, response performance and removal of the causes.The simplicity and transparency of this system allows users to carry out their work with clear objectives while incorporating learning and improvements to their work. The system contain few modules that set it apart from current smelter control systems:

- Data Acquisition and Calculation - the system collects information from various sources in the smelter from data coming from the pot controller through off-line data like lab results.

- Feeding Control (including normal control strategies and abnormality control strategies

- Noise Control

- Heat Balance Control (including normal heat balance control strategies and abnormality heat balance control strategies)

- Abnormality Detection

- Root Cause Diagnosis

- Response Plans

The system presents the analysis results in a user-friendly way that offer the users quick understanding of the current conditions and prompt for action when intervention is needed.